固体处理系统

-

配有搅拌器的大袋卸料器设备

The table blender system for solids feeding enables the addition of solids in a circulating liquid medium, from the solid product storage phase.。

-

卸袋机 - 卸载设备

The bag dump stations provide operators with an ergonomic solution for handling and manually dosing solid foodstuffs such as sugar, flour and salt, with similar grain sizes, in pre-weighed sacks or bags of approximately 25 kg.。

-

微量原料 - 装载站

The micro ingredient loading station unit is used for controlled dosing of the required amounts of small ingredients, generally in powdered form, such as enhancers, sugar, flour, salt, gums before subsequent transportation to the usage points. 。

-

过筛器

The sieving machines separate impurities and discard any agglomerates that may contain the powdered products for transportation or sieving.。

-

MBC

Double Cone Blender

The double cone blender is used to produce homogeneous solid-solid mixture. Mixing is a common process step in the manufacture of products for industries such as food, cosmetics, pharmaceutical, chemical, detergents, fertilizers and plastics.Examples of materials or substances mixed in this way include pharmaceutical granules, semolina flour, seeds, starch, coffee beans and ground coffee, cocoa, chocolate flakes or granules, powdered milk, baby food, preparations to make dehydrated soups and creams, leaf waxes, detergent granules, soap flakes, artificial fertilizers, plastic in powder, ground or pellet form, fibreglass, etc.。

-

MV

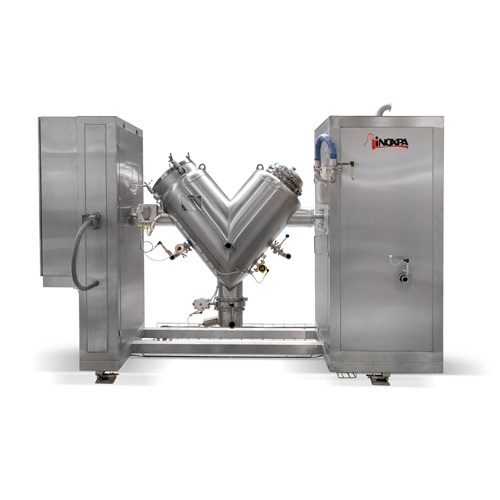

V-Type Solids Blender

The V-type blender is used to produce homogeneous solid-solid mixture. Mixing is a common process step in the manufacture of products for industries such as food, cosmetics, pharmaceutical, chemical, detergents, fertilizers and plastics.。

-

大袋卸料器设备

The BigBag unloading system enables the ergonomic handling and dosing of solid food products such as sugar, flour, and salt - with similar grain sizes - stored in BigBags of approximately one tonne in weight.。