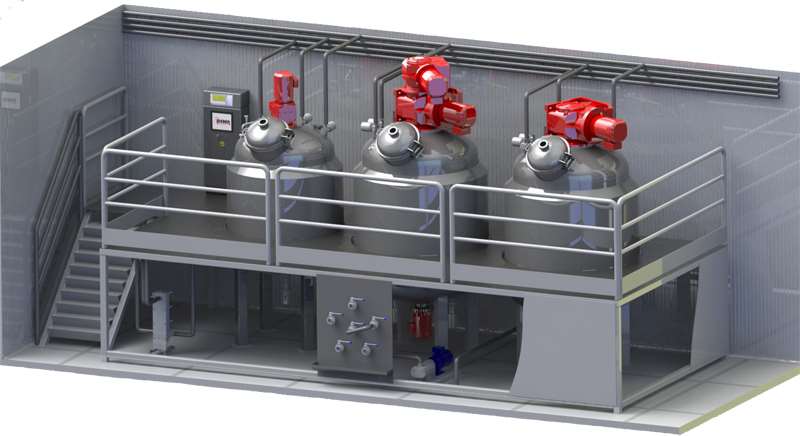

Creams can be divided into two main groups depending on their use — pharmaceutical and cosmetic/industrial.

The difference between these types lies in the fact that pharmaceutical creams contain an active ingredient (medicinal reagent) which isadded separately, whereas the others do not。

Despite this difference, however, the flow diagram provided with these instructions can nevertheless be used to explain the production process for both types.

Cream Production

请求信息

Cream Production

solucio

Cream production process

ALL EQUIPMENT

• Ensure that all equipment is clean and ready for use

• Check that all connections are correct

MELTING VAT ( (P1)

• Load the fats and waxes into the melting vat

• Close the loading port

• Heat to 90 ºC for 10–15 minutes

• Start agitation at the programmed rpm. Depending on the agitator and the type of material to be melted and mixed, between 50 and 150 rpm

• Once the materials have been melted and mixed, reduce the agitation speed by approx. 30% and the temperature to between 70 and 80 ºC until transfer

PRODUCTION VAT (P2)

• Add treated water pre-heated to 80ºC using a weighing system or a meter

• Maintain this temperature using the heating system

• Connect the vacuum system (if applicable)

• Start the counter-rotation agitator at the programmed rpm (approx. 10 rpm for the anchor and 80 rpm for the central shaft)

• Start the emulsifier at maximum speed

• Transfer the material melted in the melting vat (P1) in a controlled manner, ensuring that the flow is appropriate for the

type of mixture. The transfer can be performed under vacuum or using a transfer pump

• Once the transfer is complete, keep stirring the mixture for at least 10 minutes. Then, the emulsifier can be stopped

• Start cooling the production vat to 50 ºC using running water

• Once this temperature has been reached, add the additives: active pharmaceutical ingredients, flavourings,

colourings etc.These elements can be added under vacuum, using a transfer pump or manually via the designated port

• Continue cooling to 30 ºC and lower the rpm of the counter-rotation agitator to 6 rpm for the anchor and 40 rpm for the central shaft

• Any volatile components should be added to the mixture at this point

• Keep agitating the product at this temperature until transfer to the finished product vat (P3)

FINISHED PRODUCT

• Heat the vat to 30 ºC using the heating system

• Switch the agitator on at approximately 10 rpm

• Transfer the product from the production vat (P2) to the finished product vat (P3). This transfer can be performed

under vacuum or using a transfer pump

• If necessary due to the viscosity or other properties of the product, the production vat (P2) can be pressurised with nitrogen to a maximum of 2 bar.

FILLING

• Filling should be performed from the finished product vat using a transfer pump.

• It is recommended to install a SIL PIG system in the line. This allows any product remaining in the pipeline which lead from the transfer pump to the entry to the filling system to be recovered, thereby helping to clean the line.

文件

Cream production process

ALL EQUIPMENT

• Ensure that all equipment is clean and ready for use

• Check that all connections are correct

MELTING VAT ( (P1)

• Load the fats and waxes into the melting vat

• Close the loading port

• Heat to 90 ºC for 10–15 minutes

• Start agitation at the programmed rpm. Depending on the agitator and the type of material to be melted and mixed, between 50 and 150 rpm

• Once the materials have been melted and mixed, reduce the agitation speed by approx. 30% and the temperature to between 70 and 80 ºC until transfer

PRODUCTION VAT (P2)

• Add treated water pre-heated to 80ºC using a weighing system or a meter

• Maintain this temperature using the heating system

• Connect the vacuum system (if applicable)

• Start the counter-rotation agitator at the programmed rpm (approx. 10 rpm for the anchor and 80 rpm for the central shaft)

• Start the emulsifier at maximum speed

• Transfer the material melted in the melting vat (P1) in a controlled manner, ensuring that the flow is appropriate for the

type of mixture. The transfer can be performed under vacuum or using a transfer pump

• Once the transfer is complete, keep stirring the mixture for at least 10 minutes. Then, the emulsifier can be stopped

• Start cooling the production vat to 50 ºC using running water

• Once this temperature has been reached, add the additives: active pharmaceutical ingredients, flavourings,

colourings etc.These elements can be added under vacuum, using a transfer pump or manually via the designated port

• Continue cooling to 30 ºC and lower the rpm of the counter-rotation agitator to 6 rpm for the anchor and 40 rpm for the central shaft

• Any volatile components should be added to the mixture at this point

• Keep agitating the product at this temperature until transfer to the finished product vat (P3)

FINISHED PRODUCT

• Heat the vat to 30 ºC using the heating system

• Switch the agitator on at approximately 10 rpm

• Transfer the product from the production vat (P2) to the finished product vat (P3). This transfer can be performed

under vacuum or using a transfer pump

• If necessary due to the viscosity or other properties of the product, the production vat (P2) can be pressurised with nitrogen to a maximum of 2 bar.

FILLING

• Filling should be performed from the finished product vat using a transfer pump.

• It is recommended to install a SIL PIG system in the line. This allows any product remaining in the pipeline which lead from the transfer pump to the entry to the filling system to be recovered, thereby helping to clean the line.

| Document № | FA.Cremas.1_ES.pdf |

| Title | Fabricación de Cremas |

| File type | |

| Summary | Las cremas se pueden dividir en dos grupos básicos: las de farmacia y las cosméticas e industriales |

|

|

| Document № | FA.Creams.1_EN |

| Title | FA.Creams.1_EN.pdf |

| File type | |

| Summary | Creams can be divided into two main groups depending on their use — pharmaceutical and cosmetic/industrial. |

|

|

| Document № | FA.Crèmes.1_FR |

| Title | FA.Crèmes.1_FR.pdf |

| File type | |

| Summary | Les crèmes peuvent être classées dans deux groupes principaux : les crèmes pharmaceutique et les crèmes cosmétiques et industrielles |

|

|

| Document № | FA.TermCremas.1_ES |

| Title | Terminología para Cremas |

| File type | |

| Summary | Generalmente, una crema se define como una emulsión sólida o semisólida de productos grasos con un líquido caliente. |

|

|

| Document № | FA.TermCreams.1_EN |

| Title | Cream Terminology |

| File type | |

| Summary | A cream is normally defined as a solid or semi-solid emulsion of fatty products in a hot liquid. |

|

|